Lignacite celebrates 75 years of manufacturing sustainable masonry for Britain

Lignacite, one of the country’s leading manufacturers of sustainable masonry, is celebrating its 75th year in business, having contributed to some of Britain’s most renowned and globally celebrated architecture.

With manufacturing plants located in Brandon, Suffolk and Nazeing, Essex, Lignacite currently produces around 120,000 concrete blocks per day, enough to build approximately 100 houses.

Working closely with leading architects, specifiers, and builders’ merchants throughout East Anglia, London, and the South East, Lignacite supplies many of the major housebuilders and commercial contractors.

The Gherkin, Walkie Talkie, and Olympic Stadium are just a few of the remarkable buildings that have been constructed using Lignacite’s high-quality range of concrete blocks since the company’s inception in 1947.

Countless other developments, from residential to industrial and commercial to educational, have been built with Lignacite’s blocks. As such, Lignacite has made a notable contribution to the British landscape and built environment.

“We’re delighted to have reached this significant milestone in the company’s history,” said Giles de Lotbiniere, Chairman of Lignacite. “Looking back across the 75 years, seeing how far we’ve come and the many groundbreaking projects we’ve been involved with, gives us much to feel proud about. Remaining a family-run business, with the same core principles upon which we were founded, also provides a great sense of fulfilment.”

The story of Lignacite

Step back in time and Lignacite’s story begins with Giles’ Grandfather, Sir Edmond de Lotbiniere, an engineer and ex-serviceman. After retiring from the army, he was approached by an inventor who had produced a new mix design for concrete blocks that included wood, sand, cement, and an expensive admixture.

This proved an attractive prospect at a time when there was a shortage of construction materials and a clear desire to rebuild sites around the country following the end of World War II.

Reciting the story, Giles said:

“My grandfather started making blocks in Brandon using the inventor’s formula, but, one day, the admixture ran out. Undeterred, he continued making blocks and they turned out equally well – in fact, a little bit better without the admixture.”

Giles continued:

“It transpired that the magic ingredient was wood, which made the blocks light, warm, smooth, and robust in a fire. Inspired by this discovery, Lignacite took its name from ‘lignum,’ which is Latin for wood. To this day, recycled softwood, which would otherwise end up in landfill, is incorporated into our blocks using the same trusted mix design.”

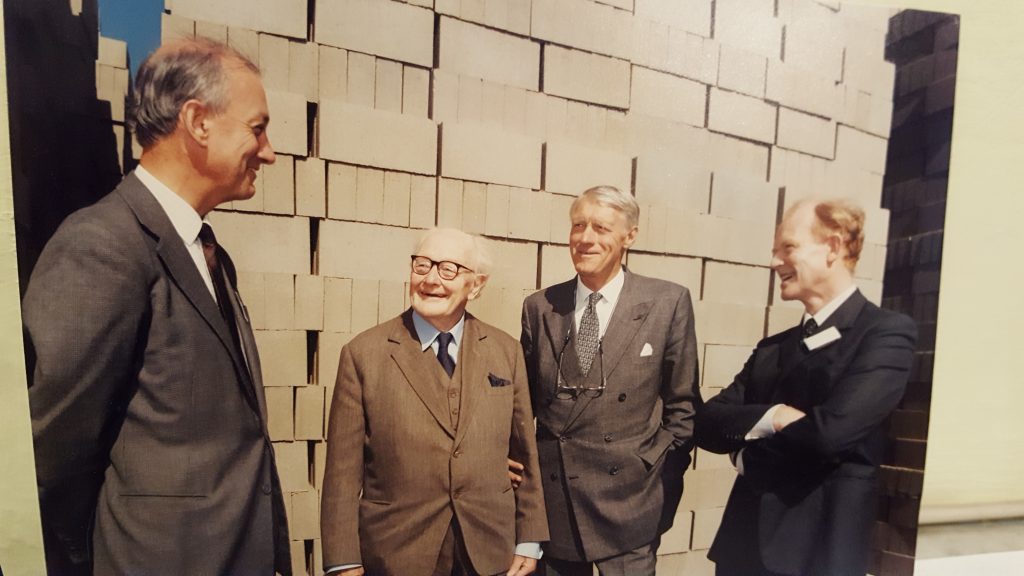

Sir Edmond de Lotbiniere (2nd from the left) and Giles’s father, Michael de Lotbiniere (on the right)

Lignacite at Trade Fair

Striving for sustainability

Throughout its history, sustainability has been central to the Lignacite philosophy, contributing to the company’s success and longevity. While the Government is now mandating an industry-wide net zero target for 2050, with interim measures, Lignacite had already committed to its own, earlier target of reaching net zero by 2030.

“We have been working towards this goal for several years,” said Giles. “We have always used a significant percentage of recycled and renewable aggregates in our products and continue to explore other materials. The Shard is just one example of this – built using 140,000 Lignacite blocks, each containing over 50% recycled material.”

Beyond the blocks, Lignacite is going much further to reduce its carbon footprint and operate even more sustainably moving forward. “We generate a significant amount of our electricity through solar panels, and we have recently implemented an app-based electronic proof of delivery system to reduce our paper usage,” explained Giles. “Our Brandon site even has its own borehole, so we recycle all of that water and use it within our manufacturing and curing process.”

Future plans

With a new manufacturing plant being developed at Brandon and a potential expansion of its Nazeing premises also on the cards, Lignacite has a clear ambition to grow responsibly, providing an exciting outlook for the future.

“We know that architects, merchants, and contractors are looking hard at their supply chains to ensure they are working with ethical and sustainable manufacturers,” said Giles. “Our new plant at Brandon will use considerably less energy than the existing one and be far more efficient. By investing in the sustainability credentials of our business, we are doing our utmost to meet the expectations of our customers and colleagues within the industry so that we remain a trusted and long-term partner for their projects.”

Elaborating on the company’s plans, Giles said:

“In the next few years, I hope we may have obtained permission to develop our site at Nazeing and be able to expand our operations there, again enhancing our productivity and, importantly, benefitting our customers. We should also be a way down the road in terms of finding another source of aggregate or having invested in, and secured, our own aggregate supply.

“So long as we keep innovating and keep using a high proportion of recycled materials, we can go on producing a very good and sustainable product that people want and need.”

For more information about Lignacite, its history, and its industry-leading products, visit: www.lignacite.co.uk