Connected Construction For Better Project Outcomes

In the past decade the Construction Industry has been digitizing at a steady pace driven by developments such as BIM & Cloud technologies. However, it’s the case that in general, efficiency increases are far behind adjacent industries like manufacturing. In part this is because construction is heavily divided both culturally and operationally between the office and the site, meaning many technology platforms are focused on the exchange of information, reporting and forecasting – at the expense of the here and how.

With always connected devices on cloud platforms we have never been in a better position to leverage real-time data in construction, so why does efficiency feel stagnant for the industry?

Historically most systems are created from the top down, formed of databases that need to be fed by individuals, about things that have happened in the past, or what they hope may happen in the future. It is especially true for project teams reporting upstream. However, being between those two states is the key for technology to unlock the next stage of productivity for everyone. It starts with the construction site, not the board room.

When something goes badly wrong in Construction, systems are the last to know because people are busy reacting. Moreover, systems are unlikely to ever understand what happened.

The parts in between the planning and reporting cycle are often the most important things for technology to have context of. If technology can view construction events more fully and in context, we open the door to levels of insight, automation and real-time analysis enjoyed by manufacturing and other industries in years gone by.

Glodon Gsite are building for intuitive and connected construction

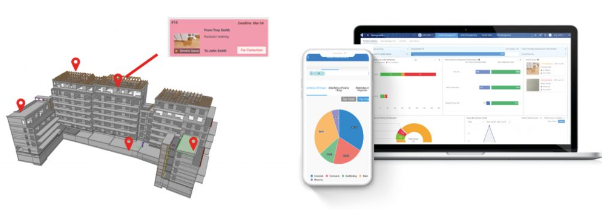

The Gsite product team have been thinking extensively in these terms in recent years. Glodon Gsite is a cloud-based software for construction management and information handling, driving the digitisation of the construction industry and the streamlining of the construction site’s work processes.

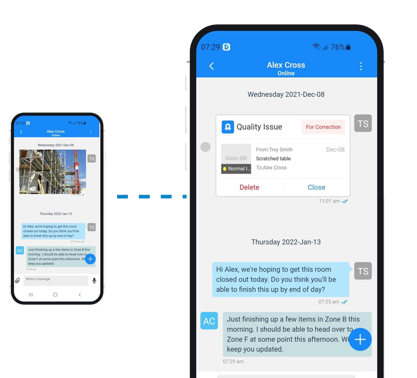

An example of increasing ‘connections’ is the Gsite innovation to include chat features with added context. We noticed a large amount of context was lost to WhatsApp in the day to day operation of projects. That increased risk and also left technology in the dark about how things are solved. We asked, “what if you could ‘switch on’ an event or issue during a chat, such as a quality issue, and have all the discussions and outcomes logged to that item.”

Not only do we bolster the concept of a golden thread of information, we enhance the ability for technology like artificial intelligence to be able to witness the line of communication and eventual outcomes that too often is detached from a platform centred around reporting and forecasting.

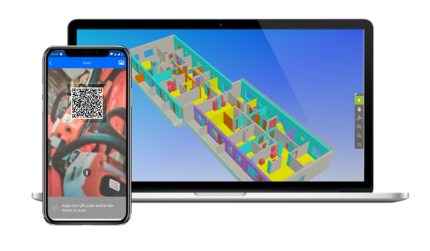

Another example of connected construction is the idea of a planned v actual programme, often failing to show a journey of how and why events may not go as planned. For Gsite we included a feature for batch created QR codes for items such as steelwork, that can be scanned and updated by all parties linking things like manufacturing, quality check, delivery an installation to the item itself.

Connecting information and processes reduces manual reporting for site teams and puts live information in front of both the site team and back office & management teams reducing the need for reports and updates. In the future, this level of consistency creates the platform for our technologies to become proactive, responsive an intelligent – leaving professionals free to add value where it matters most.

Would you like to learn more about Gsite and our digital tools?

Book a short demo here:

Email: tom.young@magicad.com

Phone: +44 (0)7500 133991

Not ready for a demo but would like more info?

Visit webpage: https://gsite.magicad.com

Gsite at UK Construction week in Birmingham, 4-6 October

Learn more here: https://tinyurl.com/2p85p95b