Timbermark offers handheld printers for timber frame assembly

Timbermark Identification Systems, the high-resolution inkjet printing solutions provider, is working with timber frame construction companies to develop the best print solutions for this growing industry.

With 17 years of experience in supplying printers for sawmills, pallet factories and panel factories, Timbermark has a wide range of handheld printers suitable for marking timber, each with unique benefits suitable for timber frame assembly.

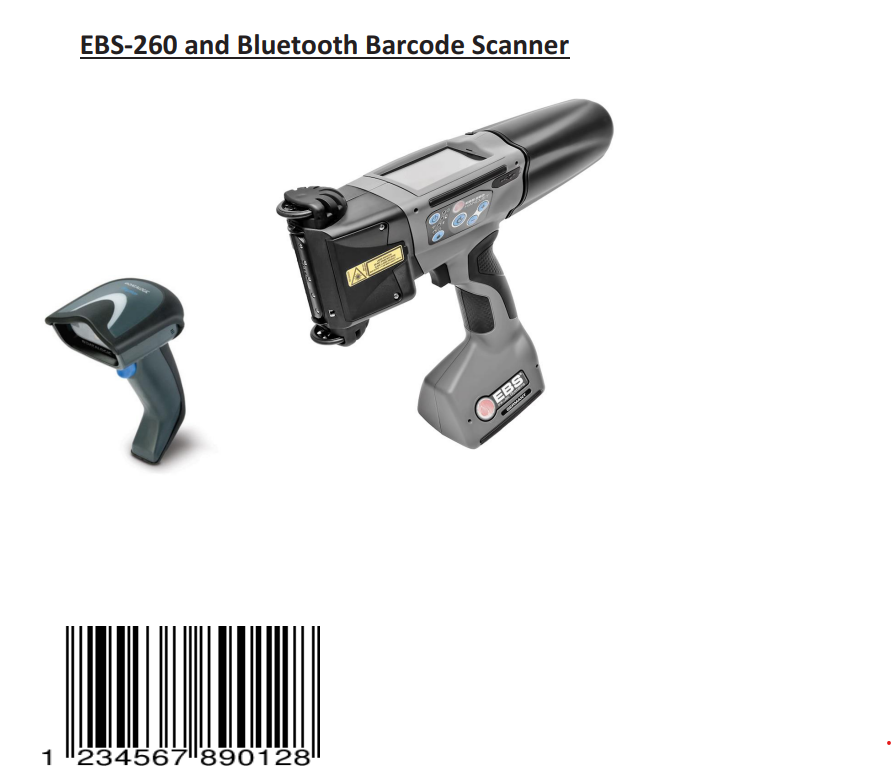

The EBS-260 handjet is a large character printer, printing 5.6cm high with 32 dots. It is suitable for printing text, logos and matrix codes onto virtually any solid surface, such as timber, paper, metal, plastic, glass, concrete. A data scanner means the handjet can reproduce machine readable code as text, making it perfect for marking individual parts in a timber frame assembly project.

If the application requires high resolution text or images then Sojet’s V1H handheld printer is an alternative option. This handheld printer offers the scan-to-print functionality of the EBS-260, but can reproduce the data in high resolution format such as a barcode or QR code. A price of £1,200 is also an attractive feature of the V1H, but the downside of this printer is the size of print: just 1.27cm high.

Larger high resolution print options are delivered by the Bentsai range of handheld printers. The B30 prints 2.54cm high with aqueous ink onto porous surfaces such as wood, card or paper and its cousin, the B35 prints the same size onto non-porous substrates like metal, glass or plastic. The Bentsai does not have a scan-to-print function, but can be programmed with multiple messages, which switch with each squeeze of the printer trigger and print in rotation. The printer comes with a guide rail to ensure precision printing and the aqueous ink cartridges can be refilled up to 4 times.

An even bigger print size can be achieved with the Bentsai B80 printer, which uses 4 of the 2.54cm cartridges to print text, logos and data 10cm high. A guide rail is highly recommended for use with this printer to keep the 4 printheads in perfect registration and they are available at lengths of 68 – 108cm.

Oxfordshire-based Timbermark, already supplies many of Europe’s sawmills and pallet manufacturers.

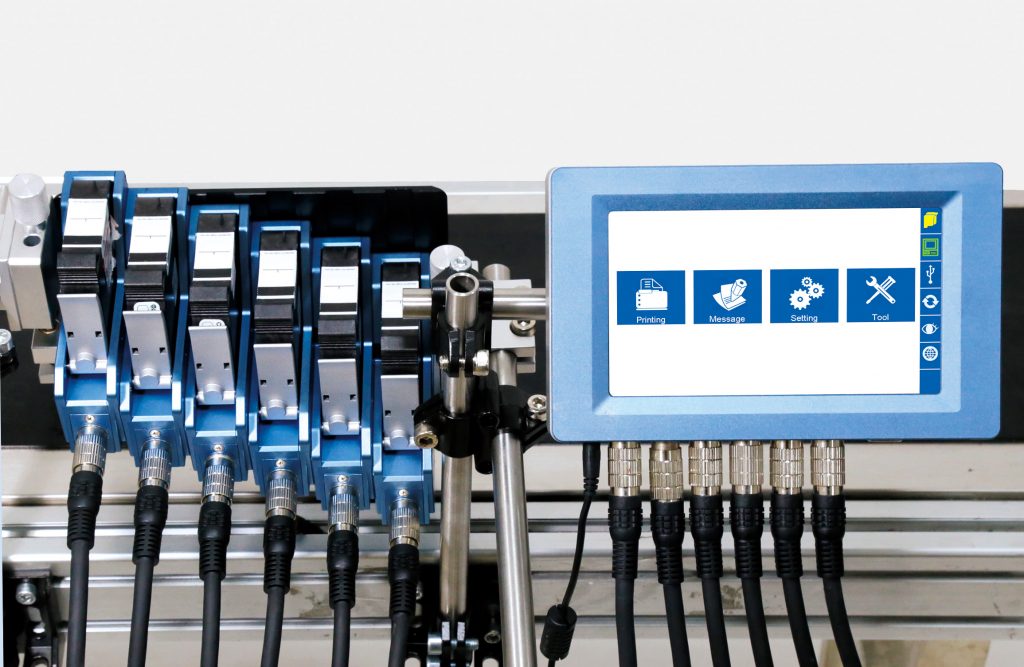

Its most popular products are the Chinese-manufactured Sojet “Elfin” range of thermal inkjet (TIJ) printers, which are simple, reliable, low-maintenance and low-cost products. Even the entry-level system (the E1, with one printhead, which costs only £1,200) has a fully-featured, touch screen controller. The Elfin printers can be installed on production lines with up to six printheads printing 7.5cm high.

Timbermark has developed a control module for the Sojet printers, which allows for easy integration with other systems, for applications such as variable data for grading C16/C24, or external data for part-numbering or live batch codes.

Timbermark is helping its customers use this technology to replace bar code labels on timber. Apart from being lower cost than labels, inkjet codes allow users to automate the application of the bar code to comply with retailer requirements. The HP technology utilized by the Sojet is sharp enough to work well on trimmed ends or on a planed timber surface.

Now operating out of Belgium as well as the UK, Timbermark is well-placed to satisfy the printing and coding requirements of the timber industry across Europe.