New Packaging Cuts On-Site Waste and Saves Developers Thousands

Geopak™ in transit

Geopak™ in transit

Trial Success at Fife College, Scotland’s first Net-Zero College Sparks Full Rollout

Whitecroft Lighting is transforming construction site sustainability with the official rollout of its smart, reusable packaging solution, Geopak™.

Designed to cut waste and help developers track valuable lighting assets, the innovation follows a highly successful trial with Balfour Beatty on a multi-million-pound Net-Zero project in Scotland.

Whitecroft says that by using the new Geopak™ system to package and transport its commercial lighting components, construction sites will eliminate tonnes of traditional carboard packaging waste, half of which is incorrectly recycled on-site, and will drastically reduce the amount of single-use wrapping used for securing boxes on pallets.

It will also save thousands of pounds in waste management costs.

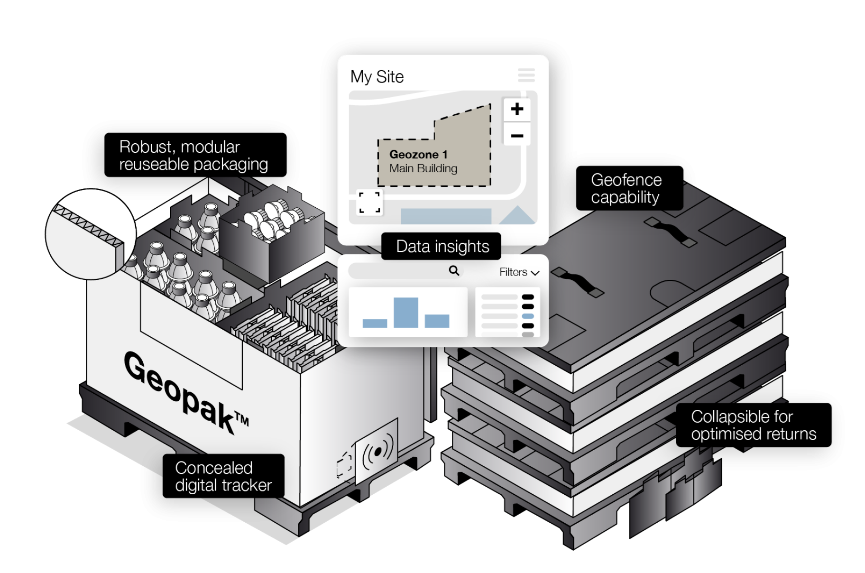

Geopak™ features a modular tote box system, made from recycled materials, designed to securely and efficiently package up to 90% of Whitecroft’s lighting range. By maximising space and reducing unnecessary packaging, it streamlines transportation and cuts waste, improving sustainability and circularity in the construction sector.

Once emptied, the totes fold flat and are returned to Whitecroft, where they can be reused for multiple projects at least 12 times, making the system sustainable, circular and cost-effective. Because Geopak™ is modular, the totes can be repurposed for various projects and packaging needs.

To prevent misplaced deliveries of its valuable products, Geopak™ features GPS-enabled tags that can be tracked on-site using geofencing to an accuracy of two to three metres. This enables developers to track each shipment in real-time and determine the precise location for efficient on-site storage, stock management, and installation.

Finally, the GPS tags also ensure that Whitecroft can quickly retrieve the collapsed Geopak™ totes for reuse in future deliveries.

Whitecroft Lighting, which is known for its pioneering sustainable and circular lighting solutions, designs products that can be refurbished, repurposed, redistributed, and ultimately recycled at the end of life.

Extending these values to packaging and transportation, Whitecroft developed the Geopak™ system in collaboration with Cardiff University and consultants PDR, mapping the entire journey, from production to installation.

The innovative concept was then put into action through a partnership with Balfour Beatty, debuting during the construction of Fife College’s new multi-million-pound Learning Campus in Dunfermline, Scotland, which will be a Net-Zero project.

Jim Brannan, Head of Supply Chain Development, Balfour Beatty, explained why the company wanted to work with Whitecroft on the development of Geopak™: “What is particularly inspiring about working on the Geopak™ project with Whitecroft is that it is not just about recycling or reusing packaging material, or even striving to meet a Net Zero carbon target. It’s about rethinking and reimagining our processes and innovating right from the design stage to the manufacturing of materials, through to the construction.”

Each Geopak™ unit is reusable at least 12 times, significantly cutting down on single-use packaging and site waste

Brannan added: “By collaborating, we planned a process and created a solution that addressed all the practical needs of each stakeholder but ultimately would help to reduce the carbon footprint of the Learning Campus development. By working together, I am proud to say that Fife College project was the first time Geopak™ was used commercially.”

Whitecroft and Balfour Beatty estimate that Geopak™ saved two tonnes of packaging waste on the Fife College project, cutting thousands in site costs, while GPS tracking reduced the risk of lost or damaged stock, streamlining storage and installation.

Now adopted on multiple high-profile projects, Geopak™ appeals to a wide range of stakeholders, from developers, architects and installers, through to project managers and property owners, because of for its sustainability benefits and tracking of expensive assets, as well as the cost savings it can help deliver. Whitecroft says using Geopak™ will take the equivalent of 100,000 cardboard cartons out of the supply chain over the next two years.

Matt Paskin, Solutions and Marketing Director, Whitecroft Lighting, explained: “Sustainability and circularity are important to Whitecroft Lighting, so we have developed a range of energy-efficient products, reduced embodied carbon in our manufacturing and designed products that can be reused and then recycled to minimise end-of-life waste.

“With Geopak™, we are taking these philosophies to the next level by combining circularity with digitalisation when developing new buildings or retrofitting existing ones. We aim to implement Geopak™ on all our major projects to help our partners meet their waste reduction targets, boost site efficiency, and use data insights to reduce the build programme.”