Reducing Embodied Carbon Through Façade Design

Mark Voss, Design Operations Manager / Associate at Wintech Façade Engineering shares his perspective on the industry’s challenges facing the reduction of embodied carbon associated with the building facade and how through early input from Façade Designers, impact can be made.

As the primary environmental modifier of the building, the façade is a key component in achieving building energy performance targets and improving occupant comfort, significantly contributing to maintaining a stable internal environment whilst keeping the heating and cooling loads of the building to a minimum.

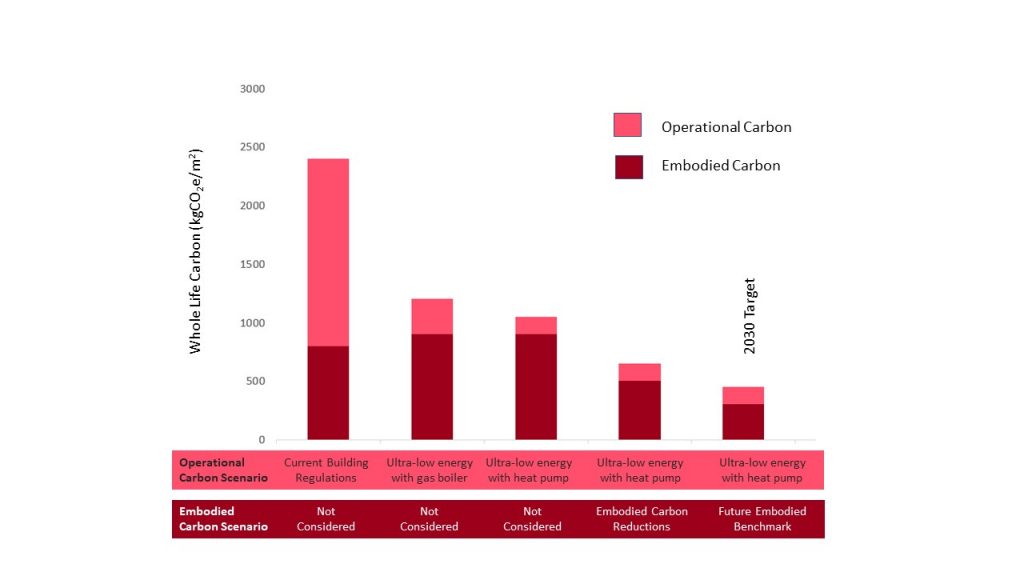

As improved targets within Part L has reduced and continues to reduce the operational carbon of buildings, reducing embodied carbon associated with the construction and maintenance of a building becomes a key focus.

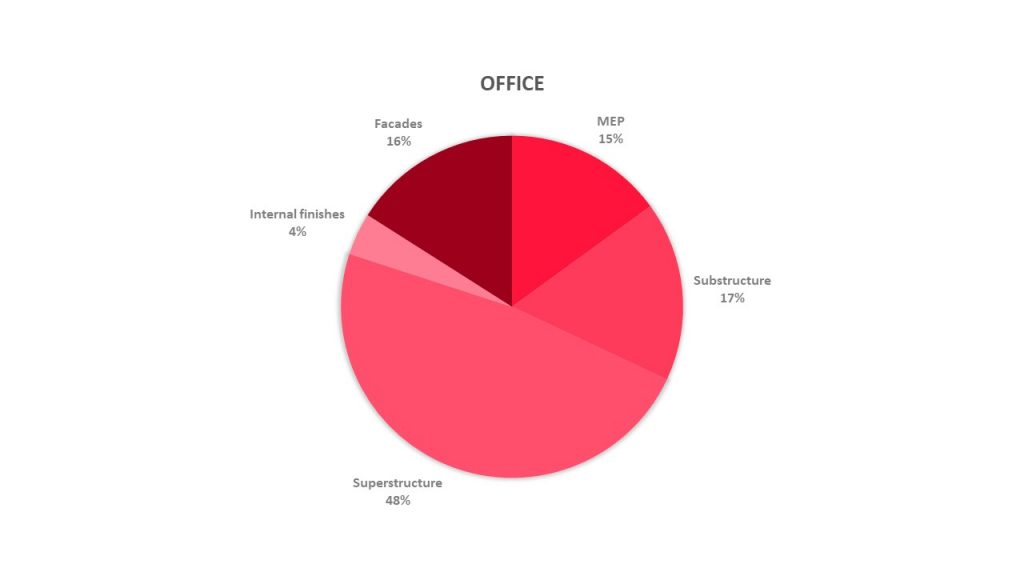

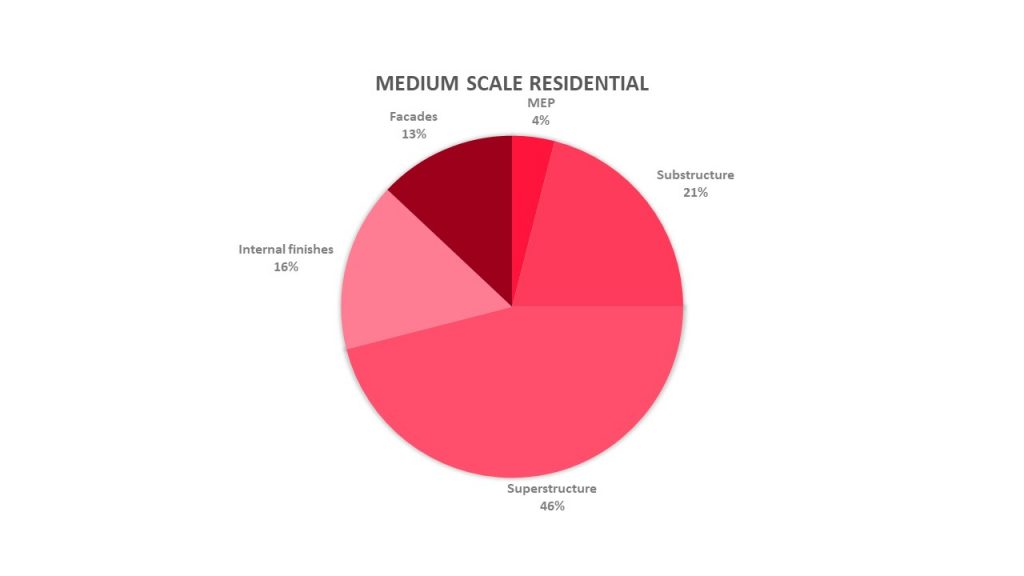

It is estimated that the façade may account for between 13 and 17% of the total embodied carbon associated with a building. As the embodied carbon associated with the primary structure reduces through lean design or by maintaining the existing concrete or steel frame, the embodied carbon associated with the façade will become more of a focal point. Where existing building stock is being upgraded, reducing the embodied carbon associated with the façade refurbishment or replacement is key. It is incumbent on architects, façade engineers and designers to reduce the embodied carbon associated with the façade.

Figure 1 – Diagram Showing Operational and Embodied Carbon Trajectory (LETI Climate Emergency Design Guide)

Material choice has a significant impact on the overall embodied carbon of a façade. The ever-increasing database of EPD’s (Environmental Product Declaration) associated with construction materials helps designers to understand the carbon associated with the production of a component. However, specifying low carbon materials is low on the hierarchy for net zero design. The design of the façade and how materials are used is a significant driver in reducing carbon. Considerations i.e., can the façade modules be adjusted to reduce wastage associated with a particular material? Or can off-site construction methods be utilised to minimise waste? Should form part of the early-stage design process.

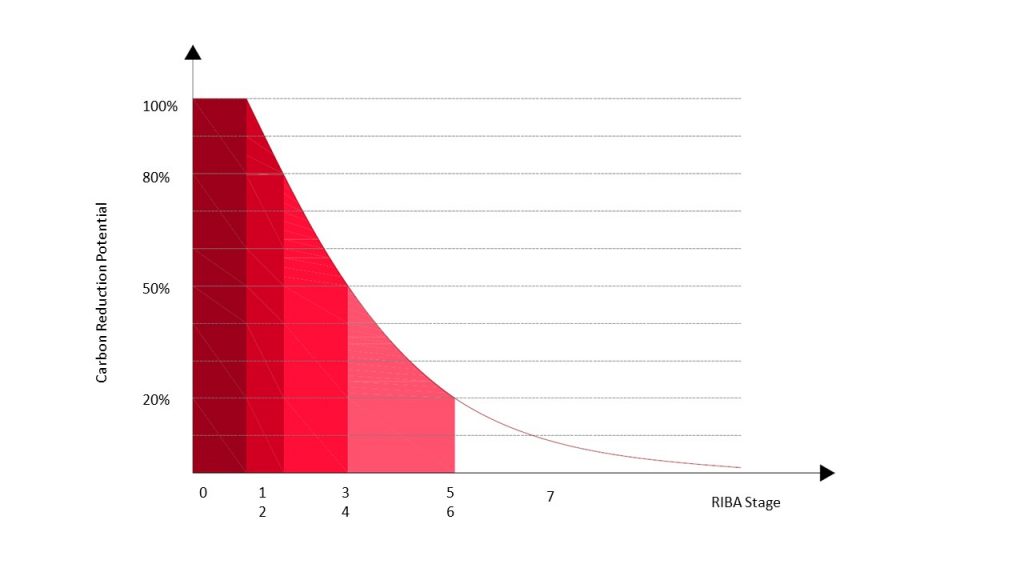

The overall wall build-up and all components associated with a particular material choice should also be considered in the early-stage carbon assessment. For example, have all the concealed metal supports required for a particular cladding material being included within the assessment? These may be ignored during the initial calculations and have a significant impact on the embodied carbon content of a particular construction. It is critical that all major components associated with the façade are considered, or it may lead to excessive embodied carbon becoming “baked in” to the building design. The opportunity to drive down embodied carbon reduces in the latter stages of a project therefore the more informed the façade design can be at an early stage; the more accurate the embodied carbon calculations will be. Early engagement with a façade engineer to understand how the façade can be constructed can also assist in reducing the embodied carbon of other elements of the building, such as the structural frame. For example, designing the façade to be loaded only at column positions may allow for a significant reduction in the thickness of the slab.

In the UK approximately 80% of the building’s that will be in use in 2050 have already been constructed. Reducing the operational carbon of these buildings is necessary, and as the primary environmental modifier, improving the performance of the façade is critical to achieve net zero targets.

Historically, introducing a new building “skin” to an existing super structure of a building would typically involve the existing cladding materials being completely removed and scrapped, with a complete new façade being introduced. It has been easier with less risk to start with a “blank canvas” than try to re-use existing elements, due to the perceived imitations of the existing system and lack of certainty of the workmanship with the existing façade construction. To reduce embodied carbon associated with the refurbishment of a building, a change in mindset is required from the design teams to assess if any of the existing façade components can be reused, refurbished, or repurposed. For example, could existing cladding panels be refurbished and used on the new façade, or could the existing cladding support rails be reused? An understanding of how the existing façade works and the limitations is important to identify where materials could be reused.

Figure 2 – CWCT Sustainability Guide 01

Future proofing the performance of the façade should also be considered in the design, using durable materials that can be adapted to improve performance. This should be balanced with lean design to ensure material is not wasted unnecessarily. For example, cast in channels could be specified rather – site drilled anchors. There is likely to be a minimal increase in the embodied carbon associated with using a slightly larger cast in channel than is required for the original design. This may allow for heavier or thicker future façade constructions to utilise the cast in channels. Cast in channels are also easier to re-use and provide greater certainty in performance than site drilled anchors.

It is clear, that given the importance the façade has in reducing operational and embodied carbon in our buildings, early engagement with a Façade Engineer is key to ensure future Net-Zero targets are met.